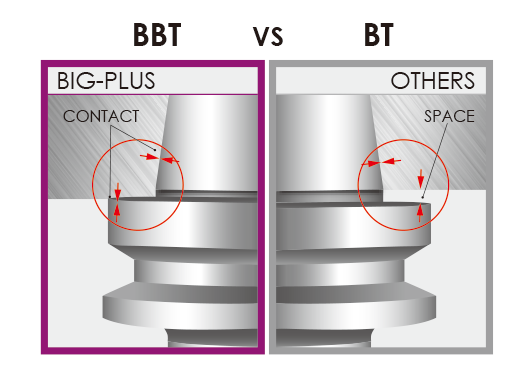

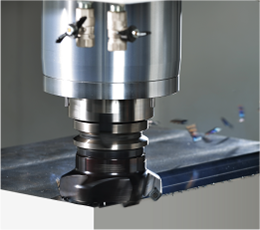

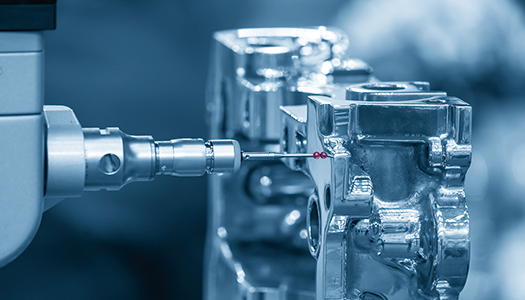

The spindle adopts the BBT type design, and the Z-axis feed system is driven by a large motor, effectively reducing errors caused by vibration and improving cutting speed and machining precision.

1. The spindle adopts the BBT type design with dual-sided constraint, enhancing cutting capacity and machining precision while reducing errors and vibrations.

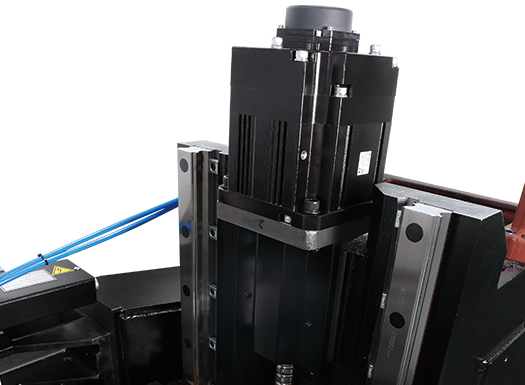

2. The Z-axis feed system is driven by a large motor with a direct drive and no counterbalance design, improving axial speed and thereby enhancing machining precision.